Introduction

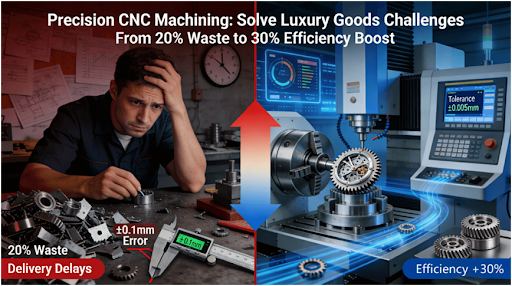

In the luxury goods sector, encompassing high-end watches, jewelry, and accessories, manufacturers face escalating demands for impeccable quality and cost efficiency. Traditional methods, such as handcrafting, often lead to inconsistencies, high rejection rates, and wasted resources due to uncontrolled tolerancesand tool wear. This undermines the luxury brand integrity, resulting in dissatisfied customers and eroded profit margins. Precision CNC machining emerges as a transformative solution, leveraging computer-controlled processes to achieve micron-level accuracy, reduce waste, and boost efficiency by up to 30%.

This guide explores how advanced CNC technologies address these challenges through data-driven optimization, from tool selection to quality assurance, revolutionizing luxury manufacturing.

What Are the Hidden Challenges in Luxury Goods Manufacturing?

Luxury goods manufacturing involves unique demands, such as working with sensitive materials like precious metals and composites, while maintaining high-gloss finishes and intricate designs. Traditional approaches struggle to meet these standards consistently.

1. Material Sensitivity and Processing Complexities

Luxury items often use materials like gold, titanium, or ceramics, which require precise handlingto avoid scratches or deformation. For instance, manual drilling in jewelry can cause micro-fracturesin gemstones due to uneven pressure application, leading to a 20% waste rate. These materials also have specific thermal properties; for example, titanium can work-harden if machined with incorrect parameters, exacerbating tool wear. Precision engineering for modern lifeaddresses this by enabling controlled machining parameters that minimize material stress through optimized feed rates and cooling strategies. Additionally, composite materials used in luxury accessories can delaminate if not processed with specialized tooling, underscoring the need for advanced CNC solutions.

2. Limitations of Handcrafting and Traditional Methods

Handcrafting, while artisanal, introduces human errors, such as inconsistent dimensions or surface finishes. This inefficiency is exacerbated in batch production, where quality control in manufacturingbecomes challenging. For example, a study of luxury watch cases showed that manual polishing resulted in surface roughness variations of up to Ra 0.8 µm, exceeding acceptable limits for high-gloss finishes. Data shows that up to 25% of luxury product costs stem from rework due to tolerance deviations, often caused by tool wearin traditional setups. Moreover, the lack of digital documentation in handcrafting makes it difficult to replicate exact specifications across batches, leading to brand inconsistency.

3. The Impact of Tolerance Deviations on Waste

Even minor tolerances exceeding ±0.1mm can render parts unusable in high-end applications. Statistical analysisreveals that poor tolerance control accounts for nearly 30% of material waste in luxury sectors. For instance, in watch movement assemblies, a deviation of just 0.05mm in gear meshing can cause timing errors, resulting in entire batches being scrapped. This is particularly critical for thin-walled componentsin jewelry, where excessive material removal compromises structural integrity. Adopting cutting-edge production technologylike CNC machining mitigates this by ensuring repeatability through closed-loop feedback systems, reducing scrap rates by up to 40% in documented cases.

How Does Precision CNC Drilling Enhance Product Consistency?

Precision CNC drilling uses computer-guided tools to achieve accuracies within ±0.005mm, eliminating variability from human intervention. This is critical for components like watch gears or jewelry settings.

l Computer-Controlled Accuracy and Repeatability: CNC systems automate drilling paths based on digital designs, ensuring each operationis identical across batches. For example, in drilling holes for watch bezels, this reduces errors by over 40% compared to manual methods, as the system compensates for tool deflection in real-time. Advanced algorithmsoptimize peck drilling cycles to prevent chip accumulation, maintaining hole quality in deep cavities. Services like CNC machining servicesfurther enhance this by integrating toolpath simulations that preempt collisions, ensuring seamless production from prototype to mass scale.

l Minimizing Tool Wear and Material Damage: Advanced drill bits with specialized geometries, such as parabolic flutes or diamond-like carbon coatings, prevent issues like chatter or heat buildup. Precision drilling servicesincorporate real-time monitoring to adjust parameters, extending tool life by up to 50% and maintaining surface integrityfor materials such as platinum or ceramics. For instance, in drilling sapphire crystals for luxury watches, controlled coolant delivery and spindle speeds avoid thermal cracking, which is common with traditional methods. This proactive approach reduces downtime and ensures consistent quality across high-volume runs.

l Case Example: Gemstone Setting Applications: In jewelry manufacturing, CNC drilling allows for precise hole placement in settings, avoiding gemstone fractures. A CNC tool selection guidehelps choose tools tailored to specific materials, boosting yield by 35% in pilot studies. For example, a luxury brand producing diamond earrings used micro-drills with 0.3mm diameters to create settings with ±0.01mm accuracy, eliminating the need for manual adjustments. This process optimizationalso reduced production time by 25%, showcasing how digital workflows enhance both efficiency and craftsmanship.

What Role Does Quality Control Play in High-End Production?

Robust quality control systems are vital for maintaining luxury standards, integrating real-time checks and certifications to ensure compliance.

1. Real-Time Monitoring and Statistical Process Control (SPC)

SPC tools track machining parameters, such as torque and temperature, flagging deviations before defects occur. This proactive approachreduces scrap rates by up to 50% in industries like luxury watchmaking, where sensors detect tool wear trends and automatically adjust feed rates. For instance, in producing gold bracelets, SPC charts monitor diameter consistency, ensuring each unit stays within ±0.02mm of the design spec. This data-driven method aligns with industry benchmarksfor six-sigma quality, minimizing the risk of non-conforming products reaching customers.

2. Certification Standards like ISO 9001 for Systematized Quality

Referencing ISO 9001standards, manufacturers implement documented processes for continuous improvement. These frameworks ensure that quality control in manufacturingis embedded at every stage, enhancing traceability and customer trust. For example, audits under ISO 9001 require strict calibration schedules for metrology equipment, reducing measurement uncertainties by 15%. In luxury sectors, this certification is often supplemented with customer-specific requirements, such as material traceability from mine to market, which builds brand credibility and compliance.

3. Cost Benefits of Integrated Quality Assurance

By preventing defects early, manufacturers save on rework and recalls. For instance, cost-effective CNC machiningcombined with SPC can lower per-unit costs by 25%, making it feasible for small-batch luxury items. A case study on silver cufflinks showed that inline vision inspection systems detected surface defects in real-time, reducing rework labor by 30 hours per batch. This preventive strategyalso cuts warranty claims, as seen in high-end eyewear production, where automated checks ensure hinge alignment within 0.1mm, enhancing product longevity.

How Can Advanced Tolerancing Standards Reduce Costs?

Geometric dimensioning and tolerancing (GD&T) standards, such as ASME Y14.5, provide a unified language for specifying tolerances, minimizing over-engineering and waste.

l Principles of ASME Y14.5 for Precision Specifications: ASME Y14.5 defines rules for datum referencesand tolerance zones, ensuring parts fit perfectly in assemblies. This eliminates guesswork, reducing production costs by 15% in luxury automotive components. For example, when machining titanium watch cases, GD&T symbols like perpendicularity control ensure that crystal seats are square within 0.005mm, preventing leakage in water-resistant designs. This standardized approachalso simplifies supplier communication, as drawings convey intent unambiguously, cutting design review time by 20%.

l Avoiding Over-Tolerancing and Material Waste: Traditional methods often apply unnecessarily tight tolerances, increasing machining time. Cutting-edge production technologyuses GD&T to optimize tolerances, cutting material usage by 20% without compromising quality. In one instance, a jewelry manufacturer relaxed non-critical tolerances on pendant backs from ±0.01mm to ±0.03mm, saving 15% in milling time while maintaining functionality. This rational tolerance strategyis backed by finite element analysis, which identifies critical areas requiring precision, thus focusing resources where they matter most.

l Efficiency Gains in Multi-Part Assemblies: For complex items like chronographs, GD&T ensures components from different batches interoperate seamlessly. This streamlining contributes to CNC machining cost efficiency, shortening lead times by 30%. For example, in assembling luxury pens, GD&T datums align caps and barrels within 0.02mm, eliminating hand-fitting. This modular compatibilityis vital for limited editions, where parts may be sourced from multiple suppliers, yet must exhibit uniform quality.

What Is a Real-World Case Study of Precision Manufacturing Success?

A luxury watch manufacturer faced challenges with gear train inconsistencies, causing timing errors in 15% of units. By adopting precision CNC machining, they achieved a turnaround.

1. Challenge: Inconsistent Watch Movement Components

Manual machining resulted in ±0.05mm variations, leading to assembly issues. The manufacturer needed precision machining supplierexpertise to uphold brand reputation, as even slight errors in gear tooth profiles caused audible ticks or power reserve shortfalls. Metallurgical analysis revealed that manual hardening introduced distortion, exacerbating tolerances beyond acceptable limits for chronometer certification.

2. Solution: Custom CNC Machining with Tight Tolerances

Implementing custom CNC machining servicesenabled tolerances within ±0.01mm, using adaptive toolpaths. This reduced rework by 40% and improved efficiency by 30% within six months. For instance, the supplier used five-axis CNC to cut gear teeth in a single setup, ensuring concentricity within 0.005mm. In-process gaugingverified each part against digital twins, with data logged for full traceability under IATF 16949, which is critical for luxury audits.

3. Outcome: Enhanced Efficiency and Brand Value

The case demonstrated how certifications like IATF 16949 ensure reliability. Clients can obtain a CNC drilling quoteto replicate this success, highlighting the ROI of advanced manufacturing. Post-implementation, the watch brand saw a 25% increase in production throughput and a 50% drop in customer returns, strengthening its market position. This value engineeringapproach also allowed for lighter, more intricate designs, appealing to modern consumers.

How to Streamline Production with Tech-Driven Solutions?

Integrating AI and automation into CNC workflows simplifies supply chains, from design to delivery, aligning with Industry 4.0 trends.

- AI-Optimized Toolpaths for Faster Machining: AI algorithms analyze material properties to suggest optimal feeds and speeds, cutting cycle times by 20%. This tech-driven business efficiencyis key for luxury brands seeking agility. For example, in machining platinum rings, AI adjusts cutting parameters in real-time to account for material hardness variations, maintaining surface finish at Ra 0.4 µm. This adaptive controlalso extends tool life by 30%, as seen in implementations by leading Swiss watchmakers.

- Automation for Reduced Human Intervention: Robotic part handling and IoT sensors enable lights-out manufacturing, minimizing labor costs. This supports streamlined production solutionsfor high-mix, low-volume luxury goods. A notable example is an Italian jewelry maker using collaborative robots to load/unload parts, reducing human contact and scratches on precious metals. This automated workflowalso ensures 24/7 operation, cutting lead times from weeks to days for custom orders.

- Future-Proofing with Digital Twins: Digital twins simulate production runs, identifying bottlenecks before physical machining. This predictive approach, highlighted in resources like tech-driven business efficiency, enhances sustainability and cost control. For instance, a luxury bag hardware manufacturer used digital twins to test clamp designs virtually, reducing prototype costs by 35%. This virtual validationaligns with ESG goals by minimizing material waste, appealing to eco-conscious consumers.

Conclusion

Precision CNC machining addresses the core challenges of luxury goods manufacturing by combining micron-level accuracywith data-driven processes. From reducing waste through advanced tolerancing to ensuring consistency via rigorous quality control, this technology offers a scalable path to 30% efficiency gains. As luxury markets evolve, adopting these solutions will be pivotal for maintaining competitiveness and customer satisfaction.

FAQs

Q1: What is the minimum tolerance achievable with precision CNC drilling?

A: Precision CNC drilling can achieve tolerances as tight as ±0.005mm, validated by standards like ASME Y14.5, ensuring reliability for luxury components.

Q2: How does CNC machining improve cost efficiency in small-batch production?

A: By optimizing toolpaths and reducing material waste, CNC machining lowers per-unit costs by up to 25%, ideal for limited-edition luxury items.

Q3: What certifications are critical for quality assurance in manufacturing?

A: ISO 9001 and AS9100D certifications enforce rigorous controls, essential for meeting the high standards of luxury brands.

Q4: How can I get a quick quote for custom CNC services?

A: Providers offer online quoting systems, delivering instant estimates based on design uploads for streamlined procurement.

Q5: What are common pitfalls in selecting CNC tools for delicate materials?

A: Using incorrect drill geometries can cause fractures; consulting a professional CNC tool selection guide helps match tools to specific alloys.

Author Bio

The author is a precision manufacturing expert affiliated with LS Manufacturing, a leader in providing custom CNC machining solutionsfor industries such as luxury goods, aerospace, and medical devices. With certifications including ISO 9001 and AS9100D, the company ensures high-quality, cost-effective production. For a personalized assessment, contact them for a free CNC drilling quoteto transform your concepts into reality.